When it comes to warehouse safety risks, workers need to be aware of potential dangers to stay safe. Also, they need to take these safety issues seriously, such as slips and falls and working around or with heavy equipment.

Every week, U.S. companies pay approximately $1 billion in workers’ compensation costs related to workplace injuries. That’s a staggering figure, but there are ways to avoid these costs.

Here are the most common warehouse safety risks along with how your insurance client’s workers can protect themselves while on the job. Be sure to share this article with your warehouse clients.

1. Heavy equipment (forklifts)

While familiarity may breed contempt, in this instance the danger is that becoming too familiar with using heavy equipment may result in lax attention and forgetting safety procedures. This is OSHA’s top warehouse safety risk.

An average of two workers die each month on the job as a result of being crushed, says OSHA. Typically, these deaths result when workers don’t handle equipment correctly. Forklift usage alone caused 70 work-related deaths and 7,290 nonfatal injuries in 2021 (latest statistics available). The number 1 cause of fatal forklift accidents? Forklift overturns, often caused by improper turning or driving with an elevated load.

All employees working with heavy equipment should have regular training. Training will help keep safety procedures like weight load limits fresh in their minds. In fact, it’s important to teach all workers how to work safely near the dangerous equipment. Even if some workers don’t handle the equipment, knowing how to avoid operator blind spots can save lives.

2. Hazard communication on warehouse safety risks

When warehouse managers don’t offer the training required for their workplace, they put themselves and their employees in danger. Your clients should have an onboarding training that includes in-depth safety orientations, identifying these warehouse safety risks. Provide additional training at regular intervals on forklift driving, proper lifting, materials handling, equipment use and more, to ensure that all employees review the safety procedures for their workplace on a regular basis.

Tailor training for different seasons and environments. And keep written manuals and documentation for reference, for workers and managers.

3 & 4. Electrical: wiring issues & system design

Ground fault electrical shock is one of the most common electrical hazards in warehouses. OSHA requires that employers use ground-fault circuit interrupters (GFCIs) or an Assured Equipment Grounding Conductor Program (AEGCP) in these settings. This use minimizes the safety risk from receptacle outlets and cord sets by covering up potentially charged surfaces.

5. Guarding wall & floor openings and holes

Unprotected wall and floor openings are number 5 on the list of top warehouse safety risks. Ensure your client knows to surround these openings with proper signage on sawhorses or other portable frames.

Every open-sided floor, platform or runway four feet or more above adjacent floors or ground level should be guarded by a standard railing on all open sides except where there is entrance to a ramp, stairway, or fixed ladder. Regardless of the height, the railing should be provided with a toe-board wherever a person can pass beneath the open sides, there is moving machinery, or if there is equipment with which falling materials could create a hazard.

6. Blocked exits pose warehouse safety risks

Your client should have multiple warehouse exits, in case of fire or other dangers. These exits should be clearly marked and lighted. They should also be free of any clutter that might slow down an emergency exit. Workers should always be aware as to where their nearest exit is.

7. Mechanical power transmission

Mechanical power transmission hazards include conveyor belts or any other powered or manually operated equipment. Typically, injuries are caused by either contact or entanglement with machinery. Injuries may range from cuts and abrasions to crushing or amputation. Employees using the equipment should always wear PPE and avoid wearing jewelry or loose clothing, and secure longer hair that may get caught. Ensure anyone using the equipment is well-trained in safety.

8. Respiratory protection

Respiratory issues can become a serious problem in warehouses when employees don’t wear PPE. The right respiratory gear helps to protect against fumes, dust, and other toxic substances in the air. A worker repeatedly exposed to these substances could develop a severe illness.

9. Lockout/Tagout

Lockout/tagout safety measures guard against the unexpected start-up of machines, equipment or the release of stored energy that could cause injuries. The unexpected activation of machinery or process equipment during maintenance operations can have tragic consequences. That’s why it’s important employees are aware of the various types of equipment and their energy sources, along with their hazards.

Related: How lockout/tagout safety can prevent accidents

10. Fire extinguishers (lack of or unusable)

Fires are some of the most dangerous warehouse safety risks – and the most preventable. First, check to see that your client has the right building permits for their business. These ensure that fire prevention steps have been taken, such as automatic sprinkler systems, fire alarms and multiple exits. Workers must know where the closest fire extinguisher is. Regular inspections should include identifying and fixing potential fire hazards.

Additional warehouse safety risks

Slips & falls

To prevent slips & falls, clear floors of any obstructions such as holes, cracks or loose cords. Clean up spills immediately. Use anti-slip floor tape and mats to reduce the risk of slips and falls.

Train workers to use fall restraints such as body harnesses, guardrails and warning lines. These items are helpful when working in other workspaces or using scissor lifts. Your client may need to use a fall arrest system such as safety nets to catch someone who has fallen.

Related: Preventing workplace slips, trips and falls

Poor material handling

Many warehouse job roles repetitive motions such as lifting, pulling and pushing. To prevent injuries, managers should optimize the warehouse for ergonomics.

For instance, objects placed at chest height rather than on the floor can be lifted more easily. Train workers on how to lift objects safely, with back straight and knees bent. Forklifts and other equipment should feature ergonomic seating and controls.

Related: Material Handling Improvements in Your Tribal Workplace

Failure to wear proper equipment (PPE)

One of the most common OSHA violations in warehouses is not wearing PPE. This preventable situation increases the risk of accidents and injuries, including crushing and impacts, breathing in contaminated air, eye injuries, and hearing loss. Warehouse managers should give all their employees a complete list of the PPE they are required to wear. Also, safety programs should explain the proper way to wear, clean, and maintain protective gear.

Falling objects

When warehouse workers are instructed to stack items up high, this can save space – but it also creates a big risk of falling objects. Creating stable stacks can lead to fewer objects falling. Place bulky items on bottom shelves whenever possible. This rule also applies to any pile of items being moved, says BigRentz.

Store and move cylindrical items with a flat side facing down. Make sure you take the time to make your stacks as neat as possible. Also, don’t load equipment beyond the weight limit.

Harmful substances

Harmful chemicals are OSHA’s second-most cited regulation in any workplace. Carefully store and label any dangerous materials; train workers in safe handling. Training should include how to use PPE to avoid contact with chemicals, plus how to clean up spills and dispose of dangerous chemicals.

Some harmful materials, such as asbestos, may not lead to an obvious injury right away. However, they could irritate and lead to serious health problems over time. Warehouse managers should monitor for these silent risks that may otherwise go unnoticed, says BigRentz.

Long work hours can cause warehouse safety risks

With today’s shortage of workers, warehouse managers may urge employees to work longer hours so that deliveries are made on time. Pushing employees to work longer can lead to fatigue and poor concentration.

Concentrating on the details is crucial for keeping every worker safe, especially where heavy equipment gets used. To avoid accidents and injuries, your client should limit the length of worker shifts. When workers get rotated regularly, they can stay more alert and focused while on the job.

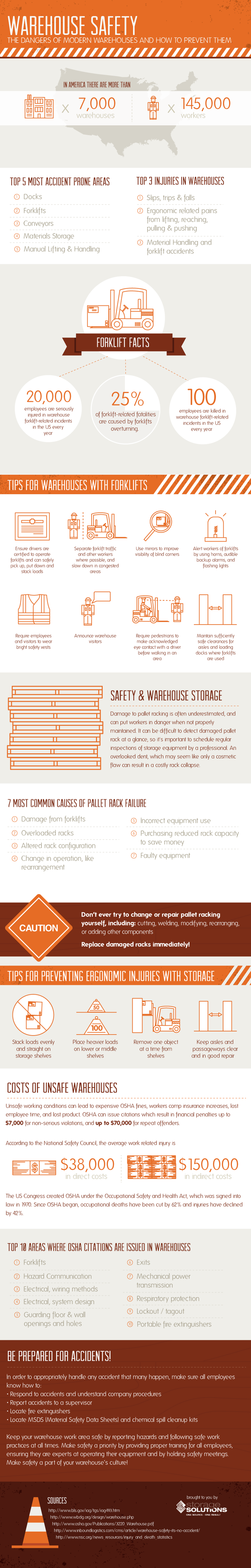

Learn more facts on warehouse safety risks and safety tips in the infographic below, provided by Atlantic Training, provider of online training materials.

This post originally appeared on Arrowhead’s corporate blog. It has been modified and updated to better reflect the needs of our tribal clients and their agents.